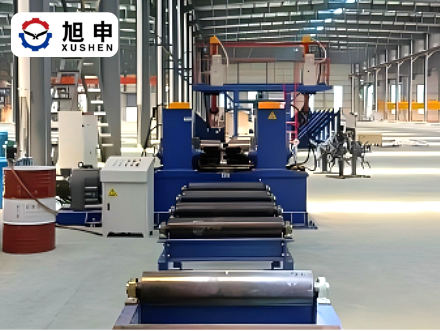

In structural steel production, H-beams often undergo deformation after welding due to uneven heat input and residual structural stress. Among these issues, web misalignment is particularly common. If the web cannot maintain a stable and properly aligned position during the straightening process, it will not only affect the force distribution on the flanges but may also lead to overall dimensional deviations, ultimately impacting assembly accuracy and the quality of the finished structure. Therefore, effective positioning and control of the web are essential foundations for achieving reliable flange straightening results.

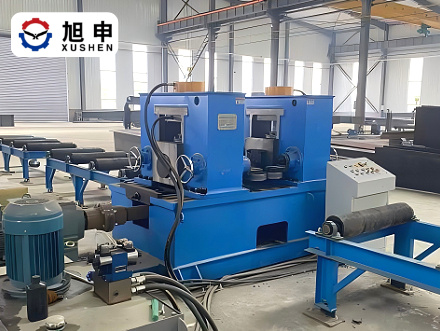

Web guiding and straightening mechanisms are designed specifically to address the misalignment that may occur when workpieces enter the straightening area. By providing proper support and guidance to the web, these mechanisms effectively limit lateral movement, allowing the H-beam to maintain a stable posture throughout the straightening process. This stable condition creates favorable force distribution for the flanges, helping improve straightening accuracy and ensuring more consistent final dimensions and tolerances.

In practical production, welded H-beams often contain residual stress and may generate impact loads when entering straightening equipment. Adjustable web guiding structures allow flexible spacing adjustments according to different beam specifications, meeting web stabilization requirements while reducing impact forces and component wear. Although the web guiding mechanism is not the most visually prominent part of the equipment, it is precisely this type of critical design detail that provides a solid foundation for stable, efficient, and reliable flange straightening in structural steel production.