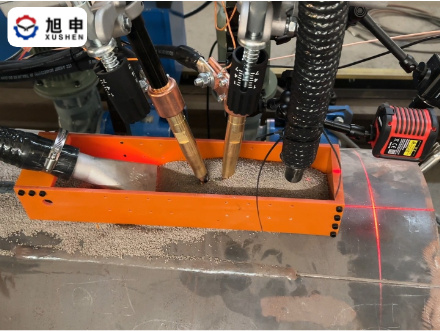

The Xushen team is dedicated to innovation in automated welding technology and has developed a high-efficiency and stable dual-wire longitudinal seam automatic welding system. Utilizing synchronized dual-wire feeding with independent current control, the system achieves high deposition rates and deep weld penetration in the production of power transmission poles, natural gas pipelines, and oil pipelines.

During operation, the system automatically regulates arc energy and welding speed, ensuring smooth, uniform, and pore-free weld seams. The intelligent seam-tracking function maintains precise torch positioning, effectively compensating for thermal deformation and workpiece deviation.

The flux circulation system supports automatic heating, feeding, and recycling, efficiently separating dust from flux for environmentally friendly and energy-saving operation. The automatic slag removal device cleans weld seams quickly after welding, ensuring smooth surfaces and structural integrity.

With advanced dual-wire welding technology and intelligent control, the Xushen dual-wire longitudinal seam welding system delivers comprehensive improvements in weld strength, appearance, and productivity. Looking ahead, Xushen Intelligent will continue to drive the integration of automated welding and intelligent manufacturing, providing global users with high-quality welding technologies and equipment.