As the manufacturing industry evolves, welding automation is transitioning from “mechanical operation” to “intelligent manufacturing.” In the past, welding relied heavily on manual labor, which meant high intensity, low efficiency, and inconsistent quality. Today, with the integration of sensors, servo control, robotic systems, and AI technologies, automated welding equipment can perform real-time monitoring, self-adjustment, and data recording, greatly improving precision and safety.

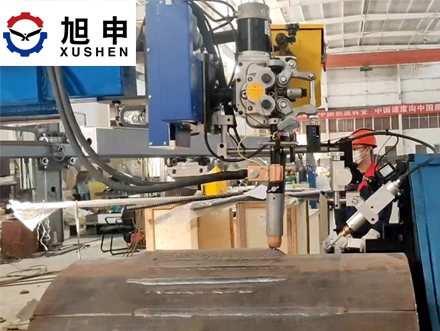

For example, welding manipulators, rotators, and positioners produced by Zhengzhou Xushen Intelligent Equipment Co., Ltd. have achieved significant progress in weld formation control, rotational stability, and multi-axis coordination. Through digital control systems, users can now perform remote monitoring and visualize process parameters, moving toward a truly intelligent welding era.

In the near future, welding automation will further integrate with big data and the Industrial Internet, enabling intelligent decision-making and predictive maintenance across the entire production process—laying a strong foundation for high-quality, efficient manufacturing.