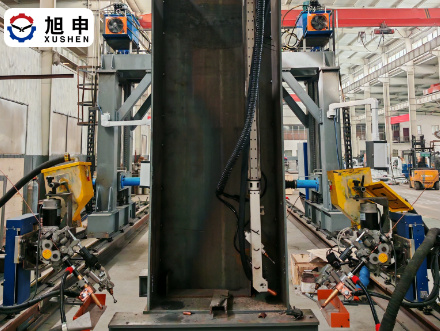

Recently, Zhengzhou Xushen Intelligent Equipment Co., Ltd. successfully completed the first trial welding operation of its SAW+MIG Dual-Wire Welding System.

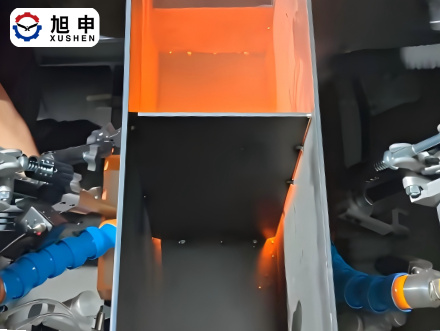

The trial process was smooth and stable, with full and uniform weld formation, bright metallic luster, and minimal spatter. All performance indicators met the design expectations, marking another significant technological breakthrough for Xushen in the field of welding automation.

This innovative system integrates dual-wire Submerged Arc Welding (SAW) and dual-wire Metal Inert Gas Welding (MIG) — two highly efficient welding processes — achieving the perfect combination of high deposition rate, deep penetration, and excellent weld quality.

Equipped with intelligent seam tracking control technology and a multi-channel synchronized control system, the system allows multiple welding heads to operate in coordination, ensuring stable weld quality while significantly enhancing process consistency and productivity.

Inspection results confirmed that the welded structures were dense, uniform, and visually refined, fully demonstrating the reliability and technological advancement of the system.

Looking ahead, Xushen will continue to take innovation as its core driving force, deepen the research and development of intelligent welding systems, and build a global high-end welding automation technology platform.

With an open and collaborative approach, Xushen is committed to providing the global manufacturing industry with more efficient, reliable, and intelligent welding solutions, driving the welding sector toward a new era of intelligence and high-quality development.