In heavy industrial manufacturing fields such as storage tanks, pressure vessels, boilers, and large steel structures, welding rotators are responsible for supporting and rotating heavy-duty workpieces. During the welding process, whether the workpiece can rotate smoothly and continuously has a direct impact on weld quality, operational safety, and overall production efficiency. As workpiece size and weight continue to increase, welding rotators are no longer simple auxiliary equipment but have become a critical component of integrated welding systems.

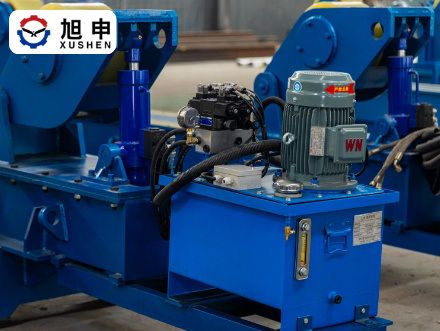

In this process, although the hydraulic system is not visually prominent, it plays a core role in equipment operation. Compared with traditional drive methods, hydraulic systems provide smoother and more continuous power output under heavy-load conditions, enabling soft start-up, stable operation, and reliable braking. This effectively reduces adverse effects caused by impact or speed fluctuations. Even during long-duration and continuous welding operations, the hydraulic system maintains consistent performance, providing stable support for the welding process.

In modern automated welding production, welding rotators typically operate in coordination with welding power sources, control systems, and other actuating mechanisms to form a complete welding solution. Proper design and reliable configuration of the hydraulic system enable the rotator to handle workpieces of varying sizes and weights with stable rotation, ensuring continuity and consistency throughout the welding process. Xushen focuses on optimizing stability, synchronization, and safety under heavy-load conditions in the design and manufacture of welding rotators and hydraulic systems, delivering reliable and sustainable technical support for heavy-duty welding equipment through proven engineering experience and systematic solutions.