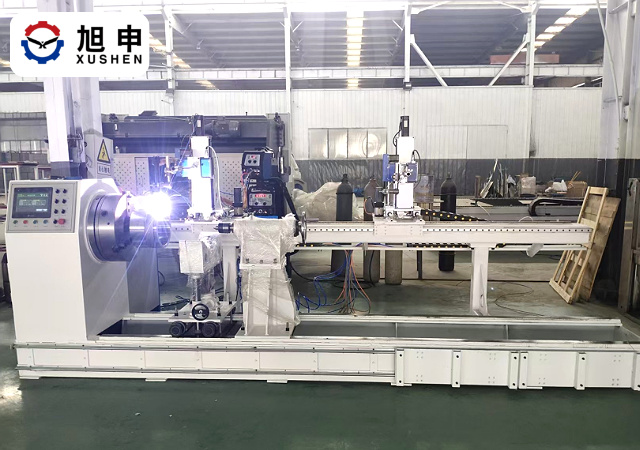

The Xushen cylindrical cladding welding machine is designed for industrial manufacturing and remanufacturing applications where high requirements are placed on the quality and consistency of external cylindrical cladding. The equipment is dedicated to the automated cladding and restoration of cylindrical rotating workpieces, with stable bead formation as its core objective. It enables various cladding processes—including stainless steel overlay, wear-resistant alloy cladding, corrosion-resistant layers, and repair cladding—to be transformed from experience-dependent manual operations into controlled and repeatable automated processes.

Conventional manual or semi-automatic cladding operations rely heavily on operator skill, making it difficult to maintain long-term consistency in bead geometry and overall weld quality. Through precise coordinated control, the cylindrical cladding welding machine ensures continuous and uniform deposition along the external surface of the workpiece. Smooth bead transitions and consistent layer formation significantly enhance cladding stability, meeting the stringent surface quality and service life requirements of cylindrical components.

The equipment is designed with a balance of structural rigidity and process flexibility, allowing it to accommodate a wide range of cylindrical workpiece specifications while minimizing the risk of deformation during welding. Welding process parameters can be stored and recalled to facilitate rapid adaptation to different materials and cladding requirements. In addition, the breakpoint memory function enables the welding process to resume after unexpected interruptions, ensuring production continuity. Key components are selected from proven industrial brands to support reliable long-term operation.

In practical production, the system is suitable for both external cladding of newly manufactured cylindrical workpieces and repair or remanufacturing of worn components. While ensuring consistent weld quality, it improves production efficiency, reduces overall costs, and shortens manufacturing cycles. Looking ahead to the evolving demands of industrial manufacturing, Xushen will continue to deepen its focus on process stability and system adaptability, promoting the evolution of external cladding from standalone equipment automation toward a welding manufacturing framework with higher consistency and stronger reproducibility.