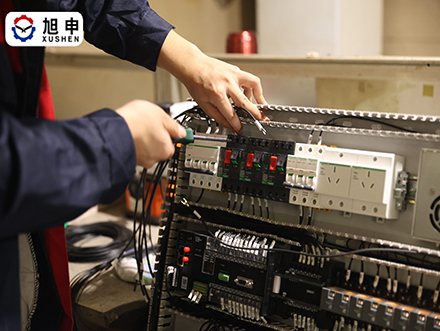

In the electrical assembly workshop of Xushen Intelligent Equipment, engineers are meticulously assembling and debugging control cabinets. As the “brain” of welding automation systems, the performance of the control cabinet directly determines the machine’s operational efficiency, long-term stability, and safety—its importance is akin to the human central nervous system and cannot be replaced.

——Open the control cabinet panel and you’ll see that power modules, relays, contactors, PLCs, and other core components are arranged in an optimal layout—each placement meticulously calculated and refined. Upon closer inspection, you’ll notice clearly organized wiring routes, securely fastened terminals, and even the spacing and labeling of wire ties strictly follow internal standards. These details reflect Xushen’s commitment to craftsmanship and an uncompromising pursuit of perfection embedded in every step of production.

——Beyond meticulous processes, Xushen ensures product stability under demanding conditions through standardized testing procedures and premium component selection. We don’t just supply equipment—we deliver integrated intelligent welding solutions widely applied in shipbuilding, steel structures, pressure vessels, and more. With over 20 years of focus in welding automation, Xushen continues to create greater value for global clients.

Looking ahead, Xushen will keep expanding its global reach, delivering even better products and services, and remain a trusted partner in the field of welding automation worldwide.