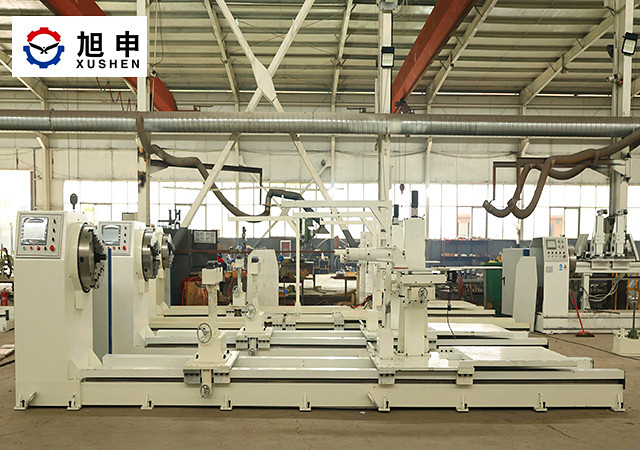

With years of expertise in welding automation, Xushen Intelligent Equipment successfully delivered an inside wall automatic welding machine to the customer, showcasing the company’s strong capability in equipment development and process control. This machine is designed for the automatic welding and overlaying of inner walls of cylinders, pipes, valves, and other components, ensuring efficient processing of wear-resistant and corrosion-resistant layers.

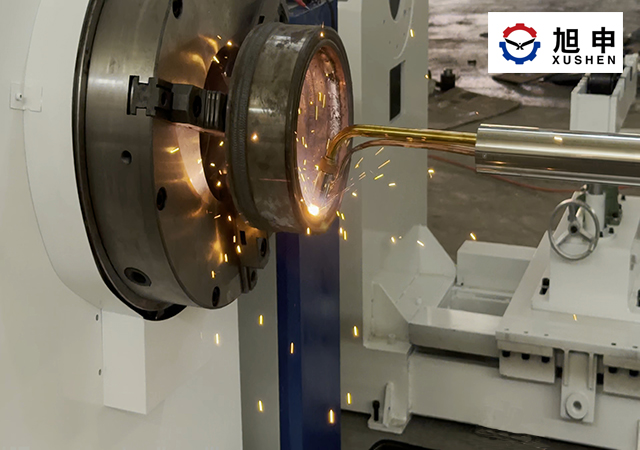

Equipped with a high-precision rotary chuck, extendable welding torch, and automatic seam-tracking system, the machine provides accurate parameter control throughout the welding process. The result is a uniform weld with a smooth surface, free of pores and cracks. Compared with manual welding, it significantly improves weld quality and productivity while reducing labor intensity and overall costs.

The successful implementation of this project solved the customer’s challenge of complex inner-wall welding and once again demonstrated Xushen’s strength in welding automation. Looking ahead, Xushen will continue to explore advanced welding technologies and provide efficient, reliable automation solutions for global clients.