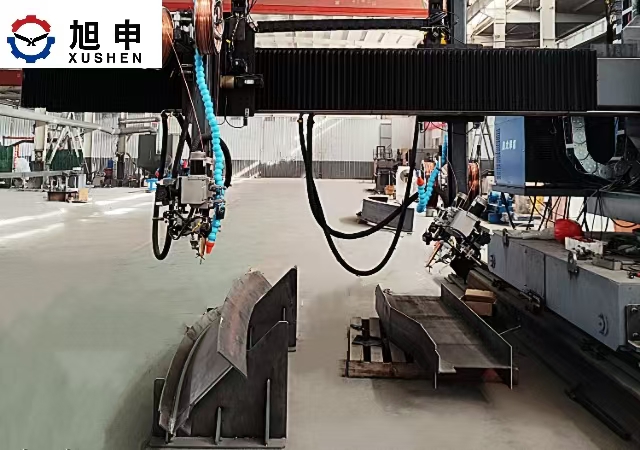

In this project, Xushen Welding delivered and implemented an automated welding system tailored to the customer’s production requirements for large metal structures. The solution was primarily applied to the fabrication of cylindrical components, long structural parts, and heavy-duty welded assemblies, addressing challenges such as large workpiece size, long weld seams, and high demands for welding stability.

During the planning stage, the engineering team conducted a comprehensive evaluation of workpiece dimensions, welding processes, and workshop layout. Based on these factors, the system configuration and workflow were carefully designed. By integrating appropriate workpiece support units with welding execution equipment, the system ensures smooth and continuous movement of the workpiece, keeping the weld seam in an optimal position throughout the welding process.

The system allows flexible adjustment of welding parameters to accommodate different product specifications and process requirements. This reduces the need for frequent fixture changes and manual intervention, while the automated operation significantly lowers labor intensity and improves workplace safety.

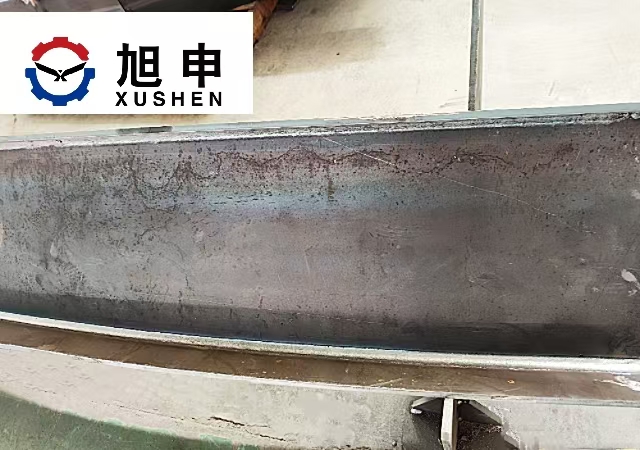

After commissioning, the customer experienced noticeable improvements in welding efficiency, weld appearance consistency, and overall production rhythm. Auxiliary lifting and repositioning operations were reduced, and equipment utilization was enhanced, providing a reliable foundation for standardized production and quality control.

The successful execution of this project highlights Xushen Welding’s capabilities in welding automation system integration, on-site implementation, and industrial application. Moving forward, the company remains committed to providing stable and efficient welding solutions tailored to real production conditions.

Fill in your contact information and requirements, and we will reply to you as soon as possible.